Intelligent software for machine tools

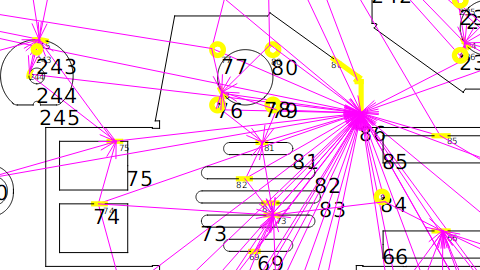

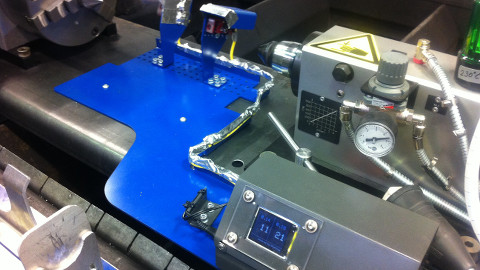

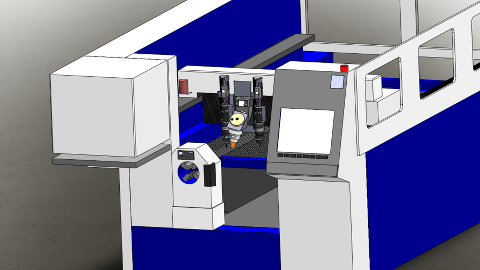

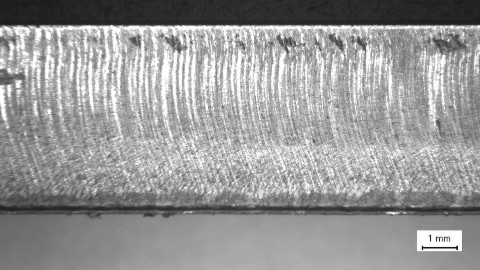

WSoptics develops new kinds of software for the machine tool market. The software is specifically designed to require little user interaction. Strong software works independently through artificial intelligence—better than a human could.